Injection Mold Design

A well designed mold is one key element for high quality, Ego Manufacturing Group maintains a dedicated staff of highly experienced mold designers specializing in Injection Mold Tool Design. Utilizing state-of-the-art solid modeling design software, our design team puts their expertise to work for high quality, completed mold tool designs.

All mould designs are validated to our clients Mold standards and mold specification. Besides we have the ability to provide prototyping and mold flow analysis service. All designed to save you money and get you production in a timely manner.

General procedures as below:

|

| |

| DFM (Design For Manufacturing) | Moldflow Analysis | Mold Mechanical Drawings |

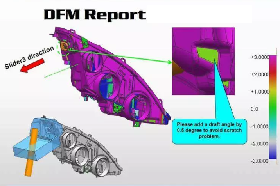

Design For Manufacturing

In broadest terms, Design for Manufacturability (DFM) — also known as Design for Manufacturing — is the process of consciously and proactively designing products to optimize all facets of manufacturing, including injection molding. DfM simultaneously helps ensure cost and time efficiencies, superior quality, regulatory compliance and end user satisfaction. Since manufacturing processes vary, there are set guidelines for DfM practices that define tolerances, rules and best practices.

DFM rejects the long-held notion that engineering and production are mutually exclusive. The methodology aligns the two in the initial design phase so any problems can be fixed early in the product development process, preventing a waterfall of potentially costly issues that could impact manufacturability — like raw materials selection, tolerances and secondary processing — can be identified and addressed.

Successfully executing DfM for complex injection-molded plastic components for critical use applications requires considerable technical expertise, which underscores the importance of partnering with Ego experienced molders. Their depth of knowledge about and beyond DFM results in efficient design decisions and related benefits, including:

Technical specifications that align with process capabilities

Moldflow analysis ensures part design elements like wall thickness, draft, materials selection, gate locations and geometries are appropriate for the proposed process, tooling and component aesthetics.

Minimal components

Using the fewest number of components in a device or machine reduces materials, ordering, and automation costs, curtails inventory challenges, and makes end user field service easier.

Simplified part fabrication and assembly

Designs that take part geometries into consideration and eliminate unnecessary features or secondary processing streamline fabrication and assembly, cutting production time and related costs.

Whether your application is medical, automotive, or another industry, if it’s critical-use in nature, a DfM study by an experienced complex injection molder is a must-have step in the process.

Moldflow analysis is a frequently used term in the injection molding industry but it is often poorly understood. The process uses a sophisticated computer program to analyze and predict the flow and cooling of plastic during all phases of the injection molding process. Since there are different levels of analytical software available, selecting the right one for your project is as important as interpreting the data for successful results.

Moldflow Analysis Levels

Undertaking moldflow simulation and analysis during the design phase ensures higher-quality parts and optimizes cycle times and reduces the number of tooling trials. The level of analysis required depends on the complexity of the part and desired outcomes.

The most basic level of moldflow analysis includes a simulation of the fill and packing phases. This helps optimize gate location, gate sizes, balance runners and process conditions.

More advanced simulations compare runner systems, mold temperatures and can even predict fiber orientation. They provide critical information for predictions regarding more complex parts and processes, and help engineers properly gauge:

a. Shrink which is unavoidable in plastic, and generally occurs because of material structure (for example, semi-crystalline or amorphous), packing pressure and wall thickness. Engineers must be able to accurately estimate shrinkage to properly size the mold.

b. Warp that results from one of three sources: unbalanced mold cooling, fiber orientation and non-uniform shrinkage. Warpage analysis reveals the causes of warpage and where warpage will occur before the mold is built, allowing engineers the opportunity to optimize part design, mold design and processing parameters to minimize deformation before production starts.

Predictive Parameters and Better Results

Other key parameters that can be predicted through moldflow analysis are:

a. Processing conditions b. Flow-induced shear stress c. Weld line location d. Air trap prediction e. Sequential valve gauging f. Cavity/part temperature differential g. Coolant temperature |

Compare More Than Cost

It’s important to note that top-level moldflow analyses are expensive and require highly skilled personnel to run them and interpret their results, and not every supplier that claims to have the capability can actually deliver. That said, don’t make a moldflow decision based simply on cost. Work with an experienced injection molder like Ego to discuss the complex geometries, tight tolerances and other intricacies of your project to determine the best moldflow option for your needs.

Copyright © Ego Manufacturing Group All Rights Reserved | Sitemap |