Injection Molding

We are plastic injection mold builder and part manufacturer with capability of mold design and part design, we focus on providing our customers a cost effective, quality excellence and shorter time frame service. Over 40 injection machines in our workshop, ranging from 50T to 1600T, that make sure we can meet customers’ unique require whether it is 5 pieces samples or 5 million large volume production. Know more details about injection molding process, please click egoplastic.com

info@ego-mfg.com us today for your project!

State-Of-The-Art Equipment

n Multi-Shots Injection Machine

|

EGO specializes in multi-shot injection molding as well as two-shot plastic injection molding. We have extensive experience in designing and building high quality molds for multi-shot and two-shot injection molded plastics for a wide range of applications.

Multi-shot plastic injection molding is an efficient and cost-effective method for molding custom plastic parts with two or more plastic resins or colors in one operation.

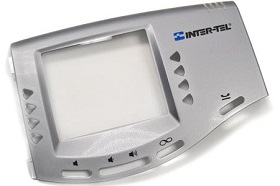

In multi-shot and two-shot custom plastic injection molding, plastic polymers from two or more injection units are applied through independent nozzles on one plastic injection molding machine to produce custom plastic parts such as soft-grip handle inserts, multi-colored parts, dashboard or instrumentation, or parts with molded seals, flexible hinges, or movable components.

The multi-short and two-shot plastic injection molding technology enables:

|

Ø Double-color and double-material parts

Ø New and wider range of designs

Ø More complex parts with a reduced cost

Ø Reduction of multiple and secondary operations

Ø Enhanced product features and appeal

Ø Improved part and end use product integrity and quality

Ø Aesthetics and more efficient production capacity

n Large Size Injection Machine

We have large injection molding machines at our plant, including 1 set 3000T, 4 sets 1600T three-color and four-color injection machines, and multiple injection machines ranging from 100T to 1200T, size is up to 3000mmX3000mm, weight is up to 100Kgs. So we can fufill most customers' volume demand, low volume from few pieces, larger volume to millions.

|

|

|

|

|

|

Contact us now to get an instant quote for your projects info@ego-mfg.com

n Reaction Injection Molding / RIM Machine

We offer reaction injection molding (RIM) services for the production of parts that are lightweight, extremely strong, dimensionally stable, and chemical-and wear-resistant.

|

|

Ego Capabilities

1. In-Mold Decoration (IMD) & In-Mold Label (IML)

|

|  |

2. Injection Over Molding

|

|  |

3. Dual-Color Injection Molding

|

|  |

4. RIM Plastic Molding

|

|  |

Secondary Operations

1. Welding includes Ultrasonic Welding, Vibration Welding, Laser Welding;

2. Printing includes Hot Stamping/Decal, Silk-Screen Printing, Tempo Printing, Laser Engraving, Label Application;

3. Painting and texture;

4. Assembly with other fittings;

5. Customized packaging;

6. Provide certification like RoHS, Reach, CE...

Know more details about secondary operations

View our successful gallary to learn more about us. Or you can send email to our sales team directly info@ego-mfg.com !

Copyright © Ego Manufacturing Group All Rights Reserved | Sitemap |